Enquire Form

HOME >> Taglus Premium

-

TAGLUS PREMIUM

Superior material properties and enhanced esthetics

Taglus Premium is an innovative aligner and retainer material with superior material properties and enhanced esthetics. As a unique engineering combination of elasticity with matchless rigidity and crack resistance, it offers the most optical clarity along with stain resistance for enhanced esthetics.

-

- Ultra-Transparent Sheets: Light transmission of Taglus premium as per ASTM D1003 is 91% makes it the most optically clear aligner material in its class.

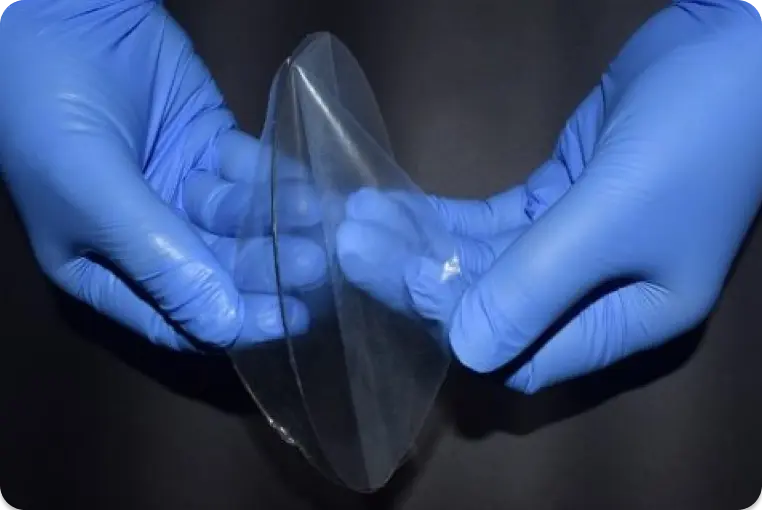

- Best-in-class mechanical properties: High tensile modulus,impact & flexural strength impart exceptional crack resistance and durability to aligners

- Predictable tooth movement : Gentle yet consistent sustained forces; help in treating diverse orthodontic cases

- Dual Protective masking : Ultra-thin, peel away masking on both sides ensures that it remains scratch-proof, moisture resistant and promotes shelf life.

Properties

In applications where plastic films are designed to withstand orthodontic forces in an aligner, the mechanical properties of polymers namely Strength, Stiffness & Toughness play a vital role. Such properties of TAGLUS Premium sheets when investigated using standardised test methods, e.g. tensile stress as per ASTM D 638: 2014 by briefly applying load in one direction the approximate results and values observed during such test, demonstrate that TAGLUS Premium is a unique balance of rigidity with elasticity. The test was performed by an NABL accreditated Laboratory complying with ISO/IEC 17025 Laboratory Management System.

Tensile Modulus, or Youngs Modulus, widely known as the tendency of an object to deform along an axis when opposing forces are applied along that axis; and defined as the ratio of tensile stress to tensile strain. TAGLUS Premium sheets having a very high tensile modulus of approximately upto 2610 MPa, tested as per ASTM D638:2014 give the best crack free aligners.

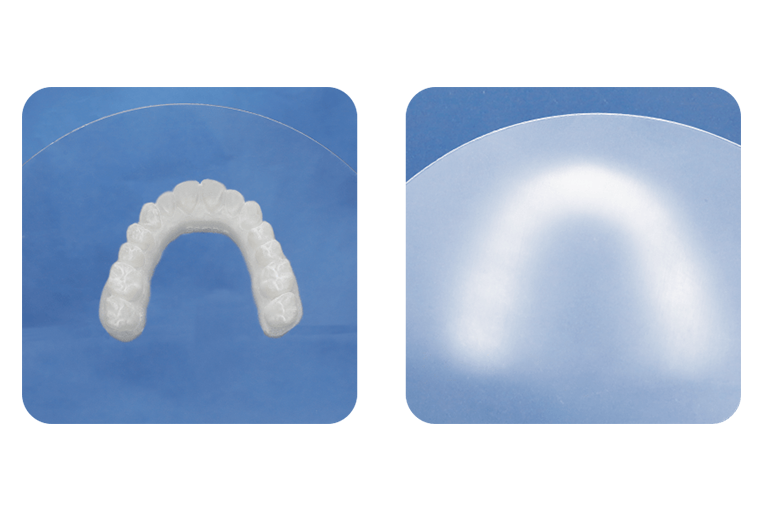

The photographs of TAGLUS Premium when compared with other PU Based aligner sheets shows a noticeable difference in the clarity of the object placed at a distance from the sheet. TAGLUS Premium has highest clarity in its class

FAQ

have any question

Is it clinically tested? How safe is it to use in the mouth?

Taglus Premium sheet passes biocompatibility testing namely Skin Sensitization, in vitro Cytotoxicity and Skin Irritation test as a regulatory requirement for demonstrating the preclinical safety of medical devices, this is evaluated in line with the standard guideline, ISO 10993-1:2018(E), Biological evaluation of medical devices – Part 1, vide UL Project #4788877994 as per document published by the US FDA “Use of International Standard ISO 10993-1, “Biological evaluation of medical devices – Part 1: Evaluation and testing within a risk management process” can be accessed at ttps://www.fda.gov/media/85865/download. Taglus Premium is “FDA compliant” means that a material meets all of the FDA’s guidelines for safety. It is made from PET which a plastic is recommended by FDA under 21CFR177.1630 guidelines for Polyethylene phthalate polymers. Being a BPA makes it a safe to use product.

CERTIFICATIONS:

- CE

- TGA

- ANVISA

How much effective tooth movement is possible when used for aligners?

Taglus premium is made specifically for aligner fabrication. It may create a gentle but consistent force leading to a tooth movement of approximately up to 0.25 mm per aligner in 7 to 15 days depending on the recommendation of certified Orthodontists

Do they offer any advantage when used for fabrication of surgical splints?

Due to its property of binding to all types of light and heat cured acrylics and the ability to adapt precisely to the model under pressure it is a very popular material used to fabricate surgical splints. Moreover, splints made from thermoformed. Taglus premium have greater stability and consistently high quality due to zero curing shrinkage.

What are the various commercially available dimensions and thicknesses of these sheets?

Available in a wide variety of thickness and shapes refer Table. Customized “Run-to-Size” dimensions are also available.

What advantage does PETG material have over the traditional PET material used in other thermoformed/ thermoplastic sheets?

Taglus premium is manufactured by the addition of special grade glycol to PET (polyethylene terephthalate glycol). This gives it three distinct advantages over its competitors:

- Elimination of the hazing effect that occurs during heating.

- Prevention of undesired crystallization.

- The inner walls of the aligner and retainer are transformed into a softer, more comfortable material for the patient.

What are working codes for Taglus Premium?

Taglus Premium can be used with several commercially available thermoforming units. For working codes, kindly refer (brochure link)

What does the peel away mask do?

The sheet is covered on both sides with an ultra-thin layer of protective covering. This peel-away masking does not get removed during thermoforming procedure. It shields the retainer from getting exposed to dust and other substances that can affect its surface. Thus the optical clarity is preserved forming an ultra-clear final product.

Is it easily available all over?

Yes, Taglus Premium sheets have an extensive global distribution. Kindly contact us on info@taglus.com for more details

What is the shelf life of taglus premium

The shelf life is 03 years subject to non-opening of vacuum-packed packaging.